With over 70 years of experience, European Springs & Pressings Ireland is a leading coil spring manufacturer. We specialise in the design and production of compression, tension, and torsion springs for a wide range of industrial, commercial, and custom applications. We provide ISO 9001-certified solutions, from precise small-batch production to large-scale stock supply.

Coil springs are among the most versatile and widely used components in engineering and manufacturing. These helical springs, which are formed from a coiled metal wire, store mechanical energy and generate force when compressed, extended, or twisted. They absorb motion, provide resistance, and restore components to their original position.

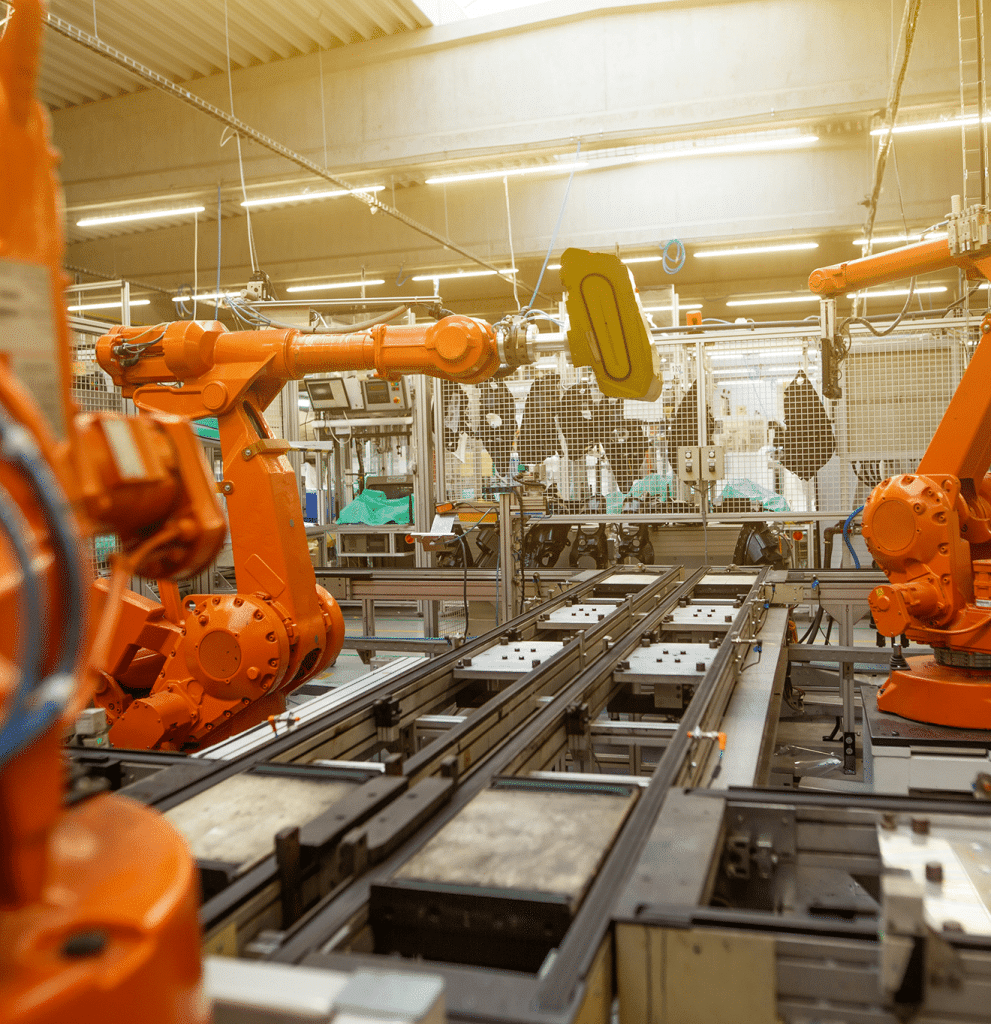

We manufacture coil springs using wire diameters from 0.1mm up to 65mm, utilising advanced hot and cold winding technologies. As part of the Lesjöfors Group, we benefit from access to high-quality materials, advanced manufacturing capabilities, and extensive resources, enabling us to serve a diverse range of industries, including automotive, rail, medical, aerospace, and heavy machinery.

As a leading coil spring manufacturer, European Springs & Pressings Ireland specialises in three core spring types, each engineered for specific mechanical functions:

Compression Springs (Catalogue: pp. 6-35)

Compression springs are the most common type of coil spring, designed to resist compressive loads. They shorten when a force is applied and are mostly used in automotive, industrial, and aerospace applications. We can manufacture a variety of compression spring styles, including cylindrical, conical, barrel-shaped, concave, hourglass, tapered, torsional, and magazine variations.

Tension (Extension) Springs (Catalogue: pp. 68-80)

Tension or extension springs are made to offer resistance when stretched. They are tightly coiled and typically feature hooks or loops at each end. These springs are more commonly used across industries such as manufacturing, agriculture, and construction.

Torsion Springs (Catalogue: pp. 90-99)

Torsion springs are designed to counteract twisting or rotational forces, producing torque as they rotate. Commonly found in products like garage doors, clips, and various industrial systems, they are used across the aerospace, medical, and electronics industries. We manufacture both single- and double-coil torsion springs, contact our team to determine which option best suits your requirements.

Each spring type can be custom-made to your specifications or selected from our standard spring catalogue. Our engineers adjust key dimensions such as coil diameter, load capacity, spring rate, and geometry to ensure a tailored design for specialised applications.

With decades of expertise and a dedicated engineering team, we understand that precise design is key to spring performance and longevity.

Using advanced CAD Cam technology, we can manufacture custom coil springs that meet your exact material and design requirements.

When developing bespoke coil springs, our engineers consider a variety of factors to ensure optimal results, from environmental exposure (including moisture, chemicals, and temperature) and life cycle expectations to performance needs, such as force range and travel distance.

Before dispatch, each of our springs undergo strict quality assurance procedures, including dimensional checks and load testing, to confirm that it performs exactly as specified.

Our production process includes both hot and cold coiling, depending on size, application, and material type. With a precision CNC coiling machinery, we are able to produce highly accurate and repeatable components, even in large quantities. In order to enhance the performance and lifespace of your springs, we offer complementary services such as heat and surface treatments, sub-assembly, and prototyping.

We primarily use unalloyed and stainless spring steel in our coil spring manufacturing. Unalloyed steel is suited for general applications with moderate temperature ranges (optimal up to 40°C, safe up to 120°C) and is ideal for static or low-dynamic load conditions. Stainless steel, on the other hand, provides excellent corrosion resistance, making it perfect for demanding industries such as marine, oil and gas, and chemical processing.

In addition, our extensive stock includes a range of specialist alloys and non-ferrous materials, such as Inconel, Elgiloy, Hastelloy, Nimonic, Phosphor Bronze, and Beryllium Copper. All of these materials offer exceptional performance in harsh or high-temperature environments. Whatever the application, we can esnure your coil spring is made from materials that guarantee reliability throughout its operational lifespan.

We are a trusted name in coil spring manufacturing, holding ISO 9001:2015 certification and being part of the Lesjöfors Group. We deliver comprehensive support throughout every stage of production, from design and prototyping to full-scale manufacturing, ensuring exceptional precision and quality.

With fast lead times, dependable stock availability, and in-house quality testing, we consistently maintain the highest standards of accuracy and reliability throughout the entire manufacturing process.

Contact our team today to discuss your project, request a quote, or arrange a consultation.

Compression springs resist compression and push back when a load is applied. Tension springs oppose being pulled apart and return to their original length when released. Torsion springs work through a twisting motion, generating torque when they are rotated.

Coil springs are used across a wide spectrum of industries, from automotive and aerospace to manufacturing, electronics, medical equipment, energy, agriculture, and consumer goods. Each application demands specific performance characteristics, making the right choice of material, size, and load capacity essential.

The lifespan of a coil spring depends on several factors, including its material, spring type, workload, operating environment, and frequency of use. We recommend regular inspections and maintenance to detect early signs of wear and avoid failure.

Yes, at European Springs & Pressings Ireland, quality is at the heart of our operations. All our products are ISO 9001:2015 certified, and we conduct rigorous quality control and testing to ensure consistent performance across every component.

Here is an inclusive list of the main sectors and applications where Coil Spring improve designs and make a positive difference.

And even if we don’t have exactly the tool we need, European Springs’ in house technology enables us rapidly to design and make complex tools, allowing us to offer more competitive prices.

© Copyright 2025 | European Springs

Designed, Promoted and Powered by SQ Digital