From manufacturing equipment to everyday products, torsion springs play an essential role. They give consistent torque, making them ideal for applications where smooth, repeatable motion matters. This reliability is why they’re widely used across many industries.

As a torsion spring manufacturer, we’re here to break down the essentials of torsion springs, from how they work, to where they’re used, and how long they last.

What is the purpose of a torsion spring?

A torsion spring is designed to store and release energy by twisting, rather than stretching or compressing. Its main purpose is to provide controlled rotational force that helps move, hold, or balance a load.

Torsion springs are valued for their reliability and precision, helping systems work efficiently while reducing strain on other components.

What are torsion springs used for?

Torsion springs are used wherever controlled rotation or return movement is required. Common applications include hinges, clips, levers, valves, and mechanical assemblies, making them a versatile spring type.

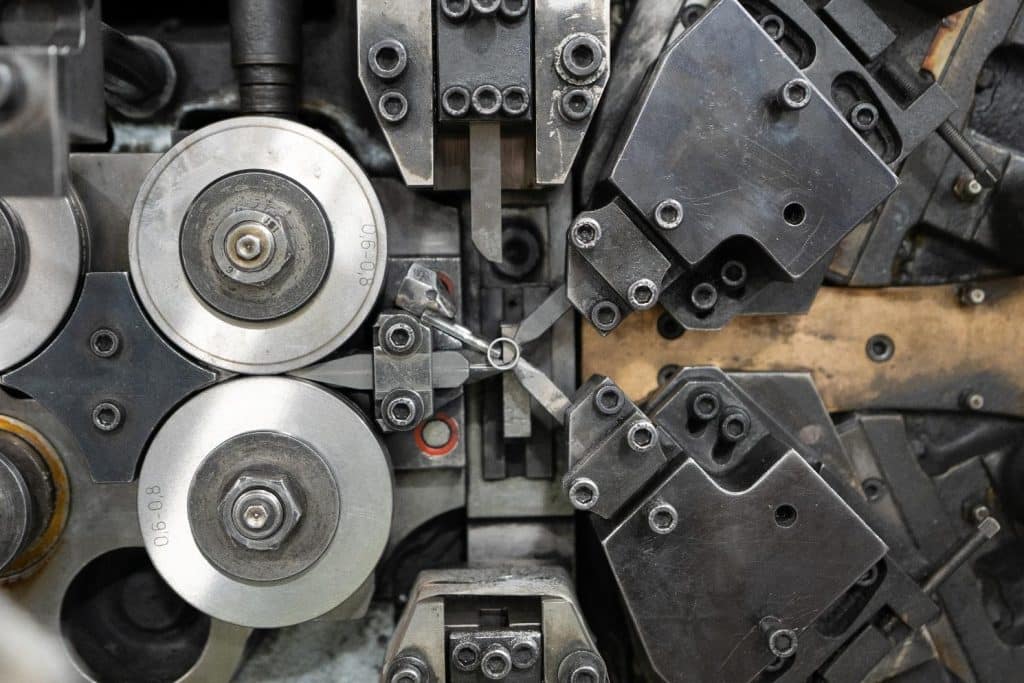

In manufacturing, torsion springs are used in automation, tooling, and safety mechanisms. They’re also found in products used in automotive, aerospace, electronics, construction, and consumer goods. One example is in garage doors and hinges, hence why these components are often referred to as garage door springs.

Their versatility makes them suitable for both heavy-duty industrial use and smaller, precision-based designs. This wide range of uses highlights why torsion spring design and quality are so important, and why it is vital to select a trusted spring manufacturer.

Torsion springs can either be single torsion, where there’s one close-wound helical coil, or double torsion, which features two sets of coils for higher torque.

How long does a torsion spring last?

The lifespan of a torsion spring depends on how often it’s used, how much load it carries, and how it’s designed. With correct specifications, many torsion springs will perform reliably for extended periods.

Several factors influence how long a torsion spring will last:

- Load and operating stress.

- Frequency of use.

- Material selection.

- Installation and ongoing maintenance.

When these factors are considered during design and use, a torsion spring can provide consistent performance throughout its working life.

What happens if a torsion spring is broken?

When a torsion spring breaks, the system it supports often stops working as intended. Movement may become uncontrolled, uneven, or completely restricted.

A broken torsion spring can lead to several issues, including:

- Loss of controlled movement.

- Increased strain on nearby components.

- Reduced safety and reliability.

- Unplanned downtime or repair costs.

Replacing a failed torsion spring quickly helps restore performance, protect equipment, and ensure operation is safe. If you need a torsion spring of a specific size, please browse our spring catalogue, where you can find details on load, lengths, and number of coils.

Why choose European Springs & Pressings Ireland as your torsion spring manufacturer?

European Springs & Pressings is an experienced torsion spring manufacturer supplying high-quality springs to a wide range of industries across Europe and beyond. We focus on precision, consistency, and dependable performance in every torsion spring we produce, whether for high-volume production or one-off prototypes.

With in-house manufacturing and an understanding of industry requirements, we support both standard and custom spring designs. This allows our clients to source springs that meet their exact specifications – such as certain surface treatments or material finishes – and perform reliably in real-world situations.

We collaborate closely with customers at every stage, from design support through to production. This collaborative approach helps ensure each torsion spring is fit for purpose, cost-effective and delivered on time.

For engineers, we’re your trusted and knowledgeable partner for torsion spring solutions.