Manufacturing springs is a complex and precise process. At European Springs Ireland, we take great pride in producing high-quality components that consistently exceed customer expectations. In this blog, we’ll explore how springs are made and how we incorporate advanced technology and rigorous quality control throughout our production process.

The Manufacturing Process

The Manufacturing Process

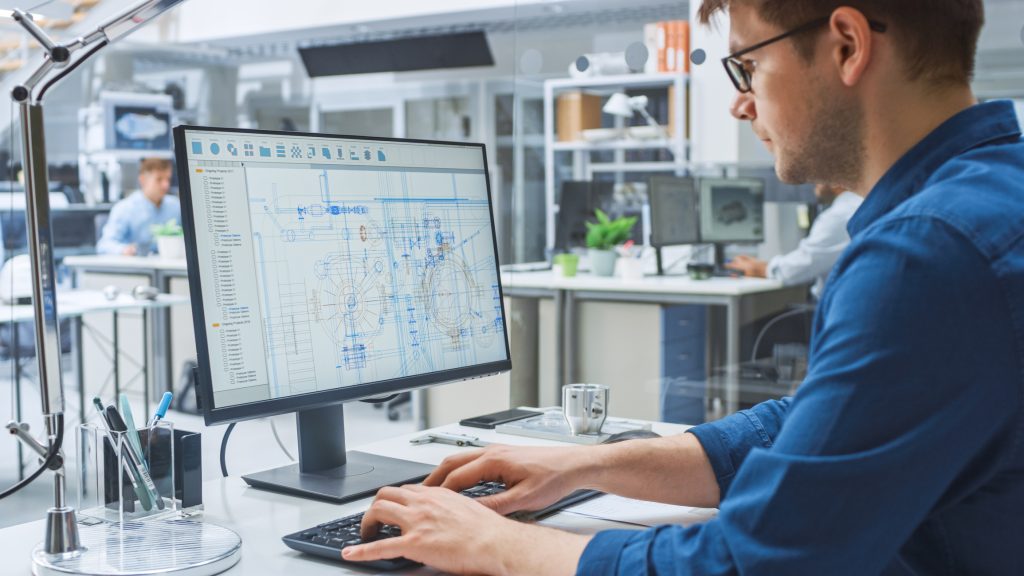

The journey begins with a design consultation, during which we work closely with our clients to fully understand their requirements and the specific applications for the springs. Our experienced engineers maintain clear and consistent communication to ensure that every product is accurately designed and perfectly suited to its intended use.

Following the consultation, we carefully select the most appropriate material based on the client’s industry and application needs. Material selection is a critical factor in spring manufacturing, directly influencing performance, longevity, and reliability.

We offer a range of high-quality materials, including:

- Carbon Steel: Carbon steel is known for its strong and adaptable material. It is suitable for a wide range of applications, such as general purpose springs.

- Stainless Steel: This material is corrosion resistant and is commonly used in harsh environments with exposure to moisture or chemicals.

- Special Alloys: We also offer speciality alloys that provide unique properties, such as high-temperature resistance or enhanced fatigue life. These materials are tailored for applications that require exceptional performance.

During the prototyping stage, we conduct thorough testing procedures, including load testing, to verify that the spring can endure the required forces. These tests also help to detect any design issues that may need to be refined. In addition, we carry out precise inspections to confirm that the sample matches the intended size and shape, which is vital to ensure that the spring functions correctly in its application.

We place great importance on customer feedback throughout the entire process, especially during the prototyping phase. This collaborative approach allows us to refine the design if needed, ensuring that the spring fully meets your requirements. Ongoing communication helps guarantee that the final product aligns perfectly with expectations.

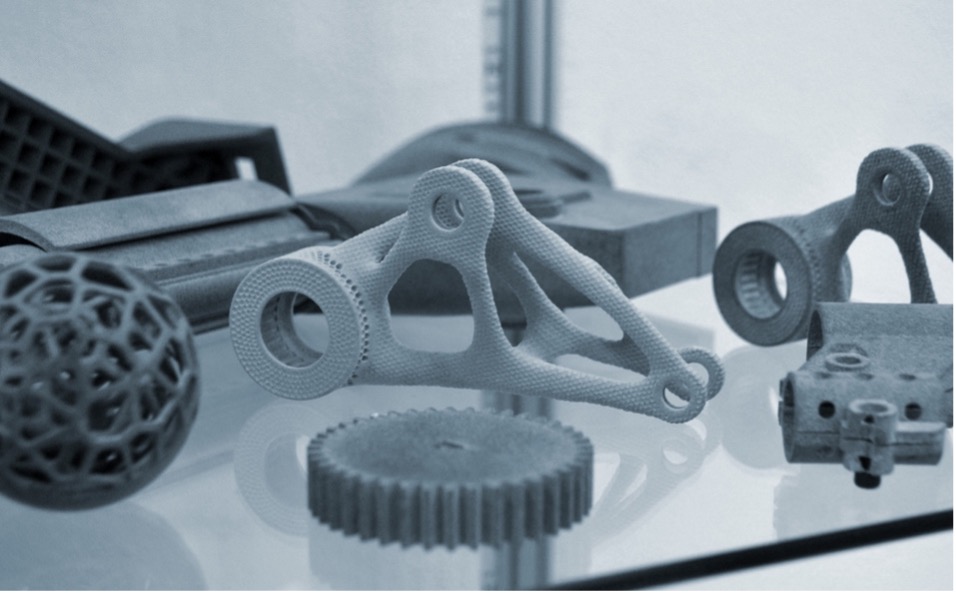

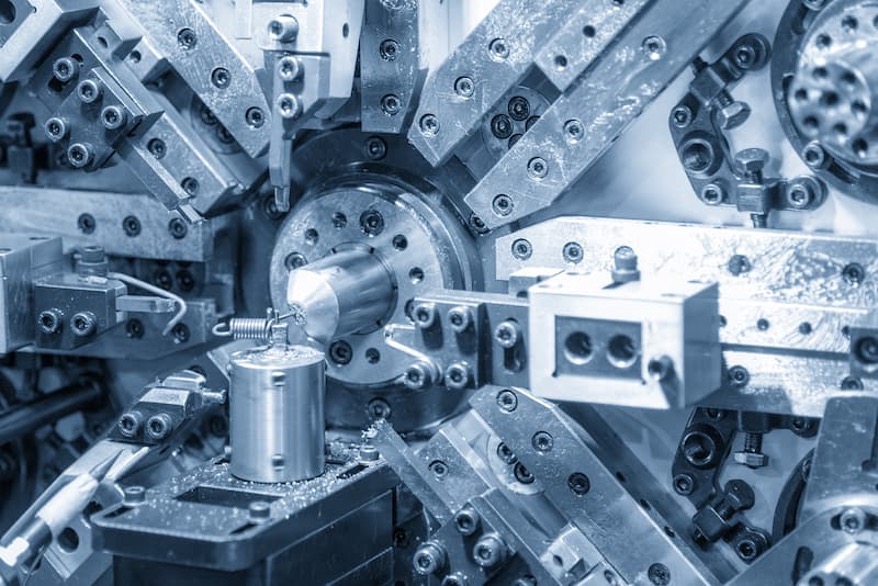

If no changes need to be made and the sample piece has been approved, we can start our manufacturing process. This starts with bending the wire into the desired form using advanced technology and machinery. Our high-tech equipment allows us to create springs in many different sizes and shapes accurately.

Spring wiring is the first step of the sprig manufacturing process, which is what gives springs their coiled, spiral shape. At European Springs Ireland, we use three main machines to help us with this process, this includes:

- Coiling Machine: Spring coiler machine is used by feeding the wire through the rollers until it peaks at a coiling point. The wire can then be coiled back to form the spring. These machines are most suitable for manufacturing of torsion, tension and compression springs.

- Forming Machine: A spring machine is more adaptable than coiling machine. It allows it to create bends, which means more spring types can be created with this kind of machine.

- Bending Machine: We utilise computer-led CNC bending machines as they offer specially placed rollers to help create bespoke wire forms for all our clients requesting bespoke solutions.

After wiring and coiling, we can move on to heat treating. This step is crucial as it makes springs stronger, more durable, and enhance elasticity, making them more resistant to wear and tear. It will also make forming and manufacturing the material easier later on in the process, as it minimises the risk of cracking and distorting.

- Shoot peening: This is a type of surface treatment that gives metal strength and creates a fatigue-resisting layer of compressive stress.

- Plating: This can enhance both how the spring looks and improve their performance as well. This can enhance appearance and improve resistance to wear and tear.

- Powder coating: A dry finishing process in which powder is electrostatically charged, sprayed onto the surface, and heated. This causes the powder to melt and form a durable layer that protects against corrosion and other environmental factors.

The final step that we make sure to do is quality control. This is crucial in our manufacturing process to make sure that each spring that has been created has no faults and that it meets our high standards. Our quality procedures include dimensional checks, material testing and fatigue testing. Assessing these factors ensures that the spring can withstand the stress of its applications and that its overall usage will be suitable for the specific application.

The quality of any product is heavily impacted by the procedures carried out during production, which is why we carry out careful and detailed manufacturing procedures to minimise damage and enhance longevity.