For those hopeful students starting out their engineering education, or those who are well into their studies, knowing precisely what will happen post-school can be a scary thought. While engineering is increasingly desirable as a role, it’s also a competitive and challenging career to get into – especially without the right knowledge and experience. So, when it comes to improving your chances of getting an engineering role, what exactly can you do?

There are a few different ways that you can tip the scales in your favour even before you complete your education, providing you with a higher chance of success further down the line. Consider these examples when looking to give yourself an edge of the competition.

Specialise Your Education

Often, engineering students tend to go the generic route when it comes to their education. While this is very useful to learn the foundations and basics of engineering, an employer will be looking for specific skills as opposed to more general understanding. So to improve the odds, the best thing you can do is focus on your strengths. Perhaps you’re incredible at analytics out in the field, or you’re better compiling data in front of a computer. Maybe hands-on work is more your style, or larger-scale collaborative projects that require a lot of group work. Whatever you’re talented in, work on that area to become a specialised candidate.

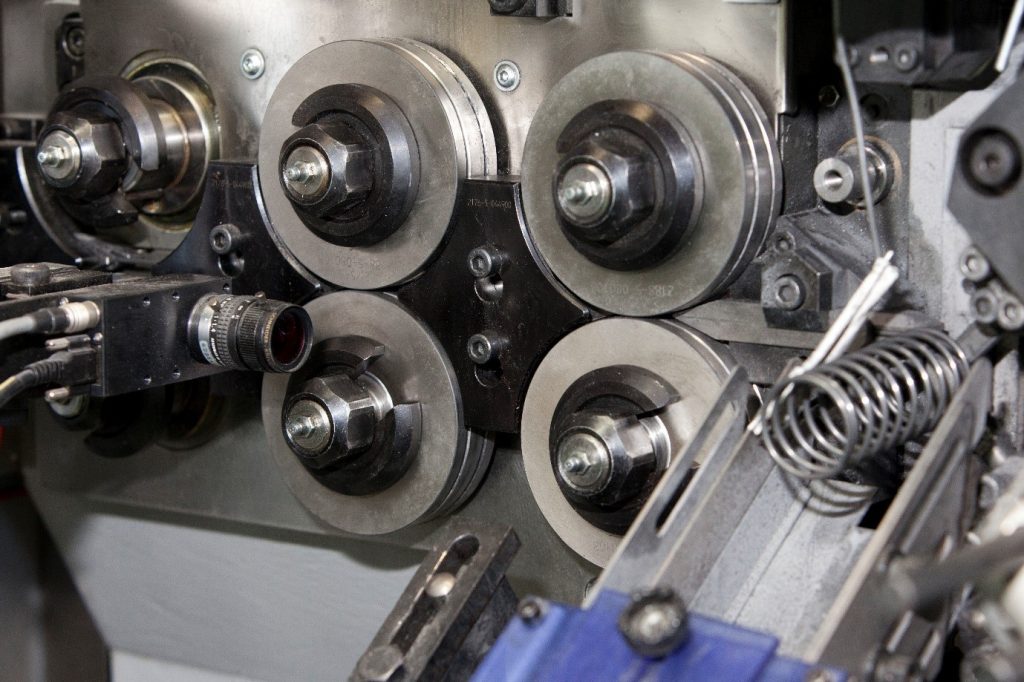

Many companies, such as spring manufacturers, choose to hire engineers based on their enthusiasm, understanding and skill in specific areas. Even engineers with the same title may have different roles depending on contract and project requirements, which means that if you’re good at something, you should certainly speak up about it. As a field that has so many individual components and requirements, there’s a niche for just about every skill set.

Develop Those Soft Skills

While having expert knowledge and training is vital to becoming an engineer, soft skills also play a massive role in your ability to transfer that information from your brain to the workplace. To improve your chances in the real world, you should be able to demonstrate skills beyond the basics in areas such as critical thinking and problem solving, as well as when it comes to managing under pressure and working to tight deadlines – both of which are very common in the engineering world.

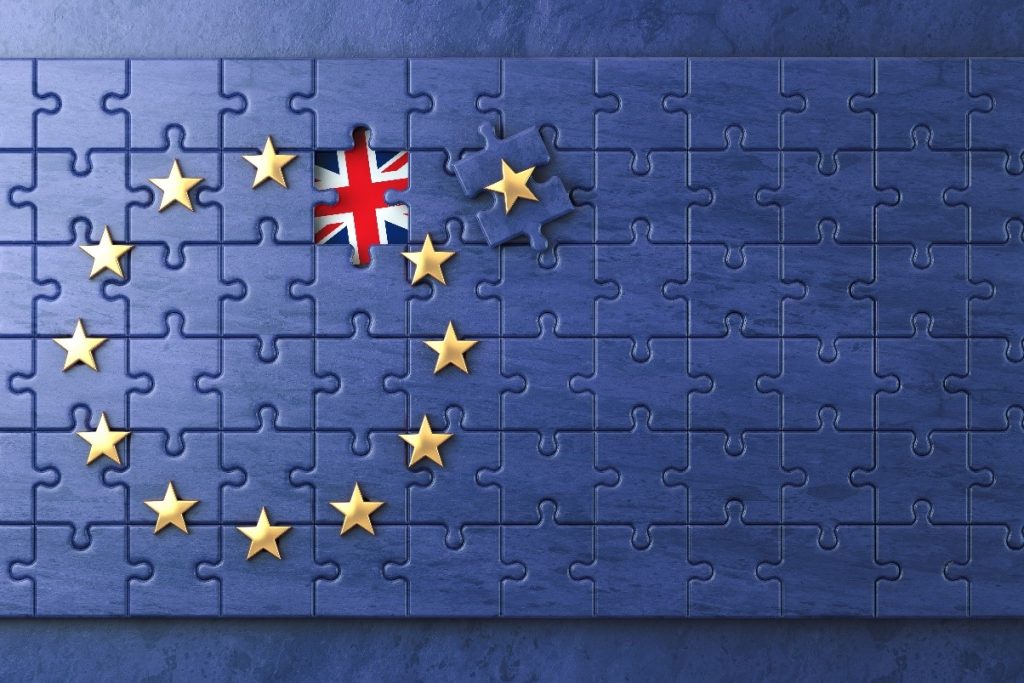

Other soft skills, like communication, leadership and even attention to detail, can all paint a picture of an engineer that’s more than worth employing. Working on those soft skills in any context, whether it’s with classmates, at a part-time job or as part of coursework, can put you light years ahead of other graduating students without those particular skills. The average engineering job is rarely completed solo, so the ability to work alongside and report to others is a vital piece of the puzzle.

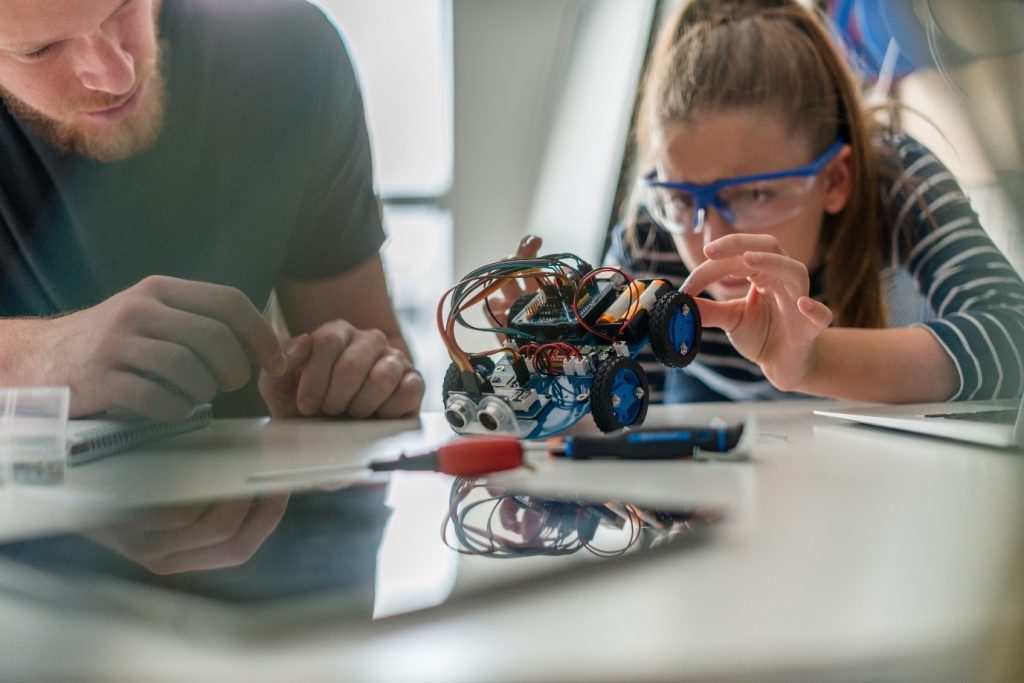

Gain Some Real-World Experience

If at all possible, gaining some proper engineering experience as part of your education should be on the top of your list. This could be through a few week’s work experience, as part of an internship or even as a class activity, but having that actual real-life experience will set you up far better to find a job when you finish learning. Even better, internships and work experience can lead to job offers further down the line, so take any opportunities you can get.

Experience proves to potential employers that you can put what you’ve learned into practice and thrive in a busy environment. Engineering experience, in particular, can prepare you well for what your future career will be like, and provides a risk-free opportunity to examine several potential career paths or job types you’d be interested in. Engineering being such a broad field, there are many areas and roles to explore. Ideally, this is the time when you can narrow down what specific field of engineering you enjoy, based on real-world understanding and knowledge that you simply can’t gain in a classroom or from books.

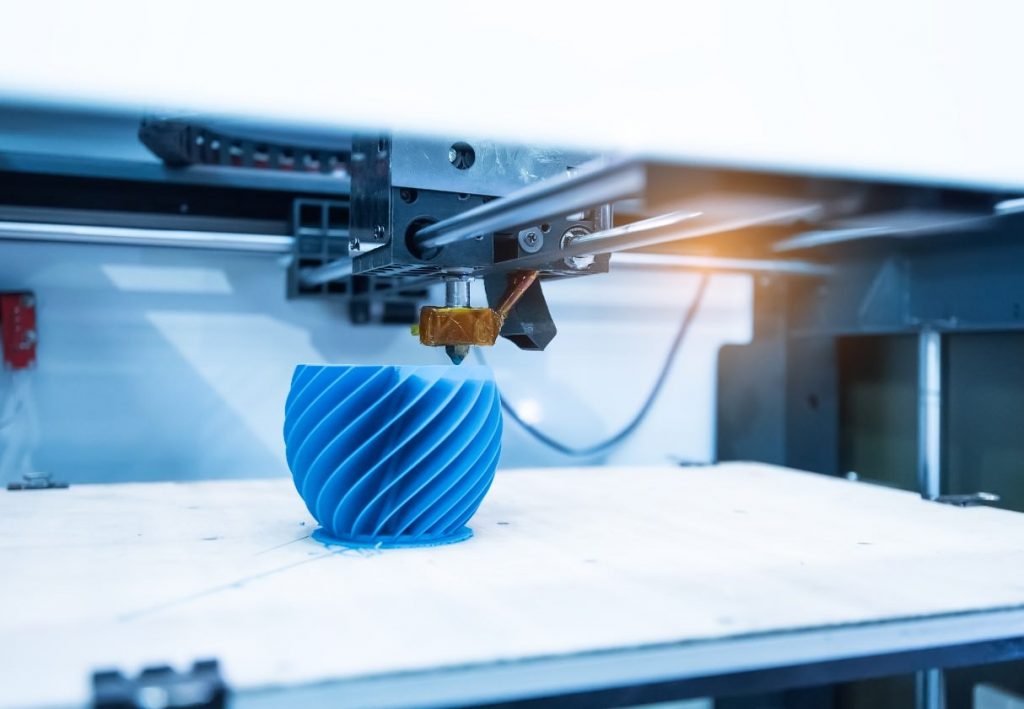

Develop your knowledge beyond the classroom

Are you learning a particular type of software or method in the classroom? Perhaps you have to use a specific tool for coursework, or a particular technique for an exam. Going the extra mile to improve your understanding of vital tools and functionalities within the niche you’d like to work in can be invaluable. In many engineering careers, a great deal of learning is done on-the-job, whether it’s the databases you’re using or the tools you’re working with. Having prior knowledge proves you’re passionate about a particular area of engineering and can set you up for success should you put the time in.

Improving your chances of securing a coveted engineering role is all about knowing what the company is looking for. If you can prove knowledge and skills in an area that you know will be valuable to that company, then you’re already in a far better position and you can beat the competition by reducing the training and learning curve required.

Pick Your Path Early And Stick To It

Engineering is a vast field, so picking an area of expertise and learning is an excellent way to both narrow down your knowledge and home in on a specific job market. While computer engineering is ever-popular and expanding, other areas such as structural and mechanical engineering hold a lot of value, as well as more unusual and scientific careers like chemical and biological engineering. Your speciality is up to you – but knowing what you want to do can provide clarity and a goal to work towards.

For engineers considering a career in the more technical side of the field, working with spring and press technology is an excellent way to transform your qualification into meaningful, and engaging, work. To find out more about European Springs and Pressings Ireland, take a look at our platform or contact us today. We’re always happy to hear from prospective engineers or those entering the world of engineering work for the first time.