The nature of the manufacturing and engineering industry is extremely fast-paced and ever-changing. With that in mind, we thought it may be useful to round up some of the most interesting and important stories from the manufacturing industry, so you can keep right up to date with the very latest developments from the sector.

Read on to find out more about how Coronavirus is affecting the supply chain, among other recent news stories affecting the industry.

Coronavirus and the Supply Chain

It’s fair to say that you can’t go on any news website at the moment without seeing a news story about Coronavirus, and the deadly virus is even having an affect on supply chains from a whole host of industries. Manufacturing supply chains are facing months of disruption, as factories around the world are struggling to operate at full strength due to the outbreak.

How Does The Future of Mobility Look?

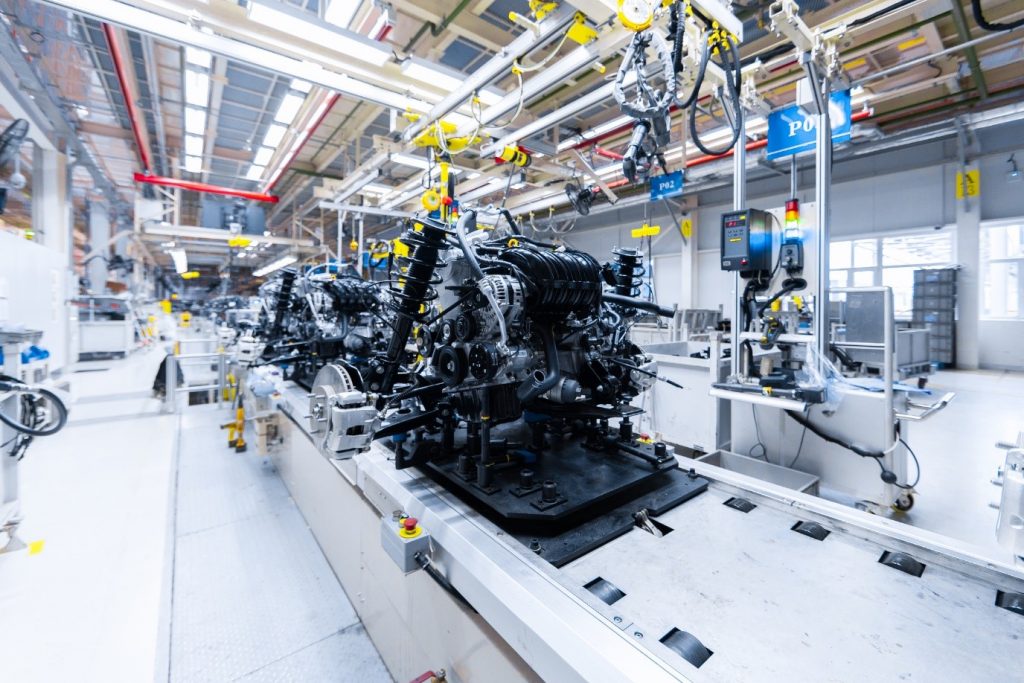

In the automotive world, there is an obvious shift in the thinking of manufacturers. With more and more emphasis being placed on the evolution of electric vehicles and phasing out diesel and petrol vehicles over the coming years. Whilst a lot has been said about the future of mobility, an article from The Engineer delves deeper into the topic, paying particular attention to the issue surrounding vehicle charging speed.

At present, the charging speed of vehicles seems to be one of the biggest reasons for consumers looking elsewhere when shopping for a vehicle. There is good reason for this, with charging ports not only being few and far between throughout Europe, but also the fact that vehicles take a significant amount of time to fully charge.

Find out more about the future of mobility by reading the article on The Engineer!

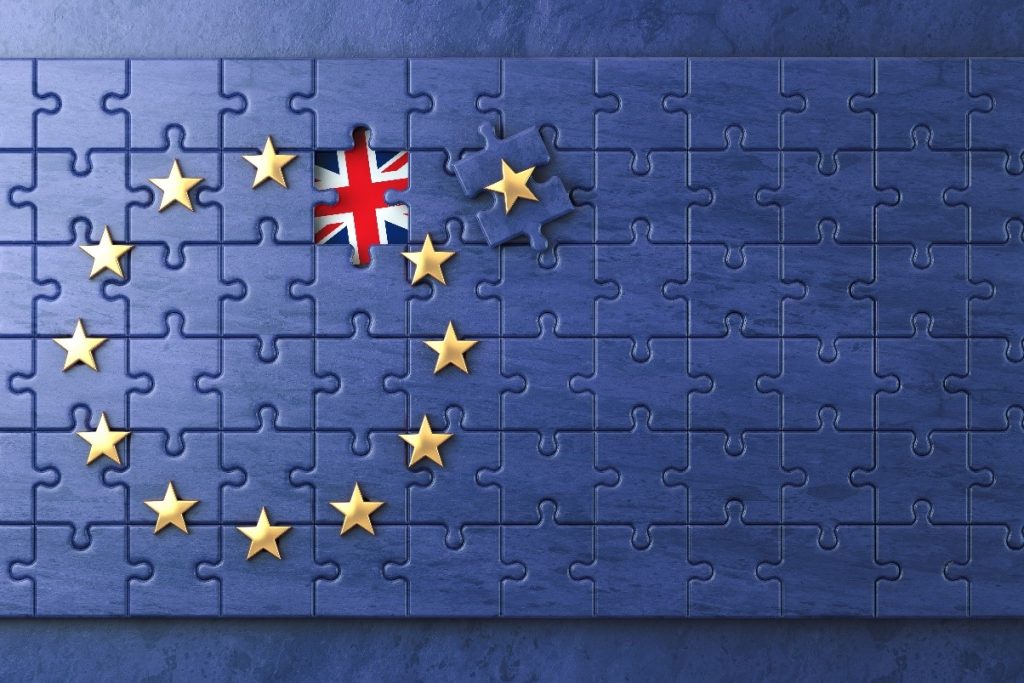

Manufacturers Will End Investment Standstill When Brexit Uncertainty is Clear

The Independent have reported that manufacturing companies will only increase investment when the UK’s ‘direction of travel’ relating to Brexit is clear. The news came about from a survey conducted with over 330 companies in UK manufacturing by Make UK. The survey suggests that one in four companies view increasing investment allowances as the main priority for the government, with over a fifth of respondents calling for a cut in corporation tax.

You can find out more about the manufacturing survey by visiting The Independent’s recent article.

Making The Most Of Big Data In Manufacturing

With advancements in all manner of technology, from augmented reality to 3D printing, there is an added pressure to ensure that technology is integrated into existing processes as efficiently as possible from manufacturing bosses. With an ever-increasing pressure from customers, it’s imperative that your business makes the most out of big data, integrating it into each and every step of the manufacturing process to create a more streamlined approach to manufacturing products.

You can find out more about big data in manufacturing by visiting the full article on Manufacturing Management’s website. The piece takes a closer look at why data is so important in manufacturing, whilst also addressing what manufacturers need to do once they have collated and interpreted data.

How To Develop A UK Manufacturing Workforce For The Future

Much has been made about the state of the manufacturing workforce in recent years, with many older and vastly skilled employees coming to the end of their careers, there is a significant shortage of younger workers entering the industry. With that in mind, you may be wondering just how your business can develop a workforce for the future, especially if you are in a situation where many of your key employees are close to retirement.

With an estimated 80% of manufacturing companies struggling to recruit the talent that they need to compete within their field, it’s pretty clear that things need to be done. This article from PES Media gives some great recommendations on how you can succeed in developing young talent within the manufacturing workplace, so it’s well worth a read if you’re in the process of training younger members of the team.

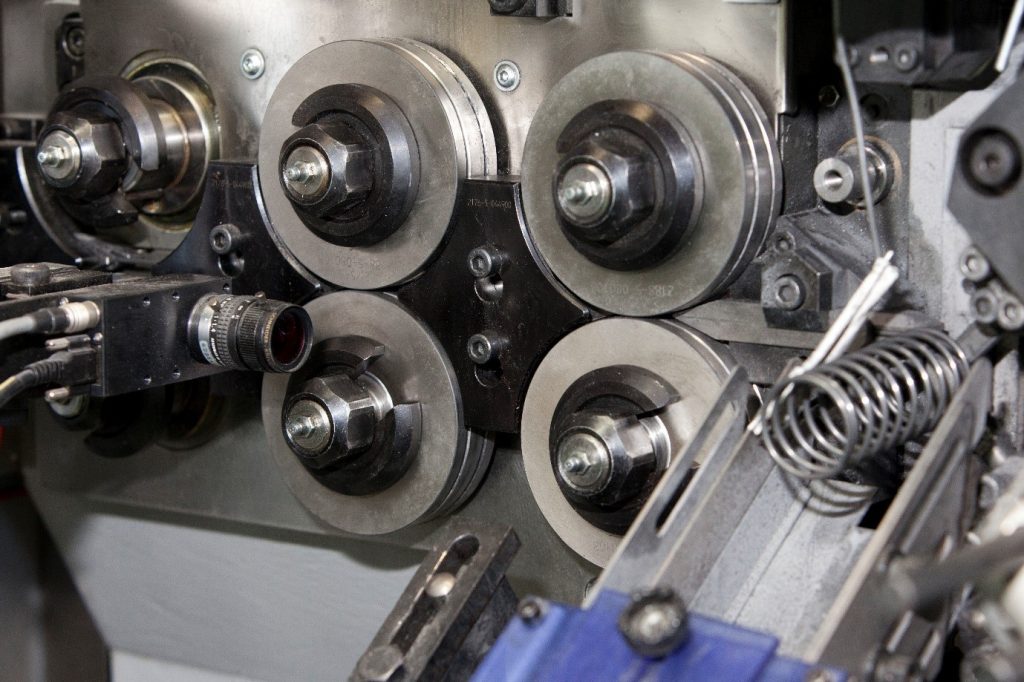

The team here at European Springs & Pressings Ireland pride themselves on being at the very forefront of spring manufacturers in the UK. We know that it’s absolutely vital that we take the time to understand everything that is going on within the engineering and manufacturing industry, so we can best serve our customers and future proof our business operations. If you would like to keep right up to date with the very latest news coming out of the industry, be sure to check in on our blog regularly for the updates from the sector.