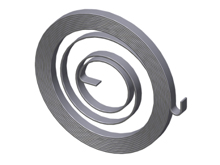

Motor springs can be used instead of torsion springs, where the desired application requires several turns of torsional force. The versatility of motor springs means they can be locked onto an attached shaft using a catch or fastened to a pin or housing edge.

What is a Motor Force Spring?

Motor force springs are designed to perform like a constant force spring, meaning that this type of spring can supply rotational energy from the attached shaft.

In most cases, motor springs are made from stainless steel with longevity depending on the size and max torque. The provision of constant force is evident due to the motor force spring exerting a restraining force that resists uncoiling.

Motor Force Spring Design

Motor force springs have a torsion design but can be manufactured to provide more turns than a torsion spring — some can offer 10 to 20 turns of force. When an increased amount of turns are needed, you can attach several motor springs together.

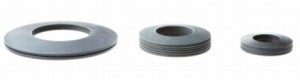

Torque and spring size can have a lasting effect on the lifespan of a spring. By stacking multiple springs, you can counteract any future problems that may occur when using a single spring.

We create springs that are secured with a nylon band to improve performance. We would always recommend that during fitting, the springs are lubricated to reduce friction — if you do not lubricate the springs, you could experience up to 20% loss of force.

Motor Spring Applications

The electric power industry regularly uses our motor force springs in backup devices. In stainless steel forms, motor springs are intricately designed to maintain longevity even within the most demanding applications.

Another example of constant force motor springs applications is within the operating mechanism for film cameras, power generation, timers, and cable retractors.

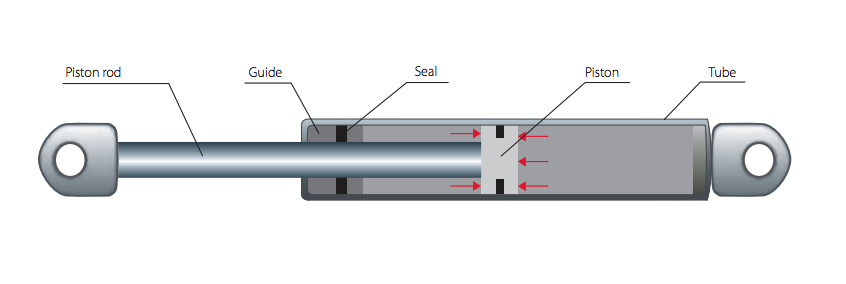

These springs can be locked onto an attached shaft using a catch or fastened to a pin or housing edge. The springs with the smallest internal diameter should be placed in housing with the outer hook located around a pin. You can also fit the springs into larger housing, although the force will be lower. However, it is feasible to increase the diameter of the inner coil for placement on a larger shaft.

The Difference Between Motor Springs and Clock Springs

At first glance, clock and motor springs are visually similar, both resembling a spiralling circle. However, it’s important to distinguish which spring to use in a specific application for the most effective and safest result.

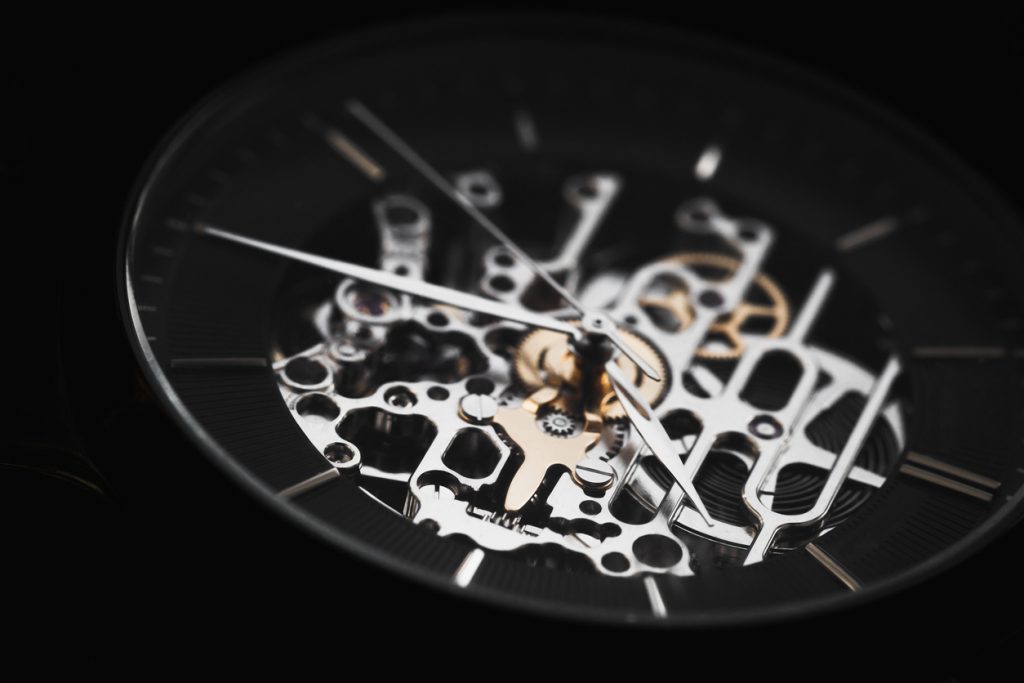

Clock springs are coil friction-free and manufactured from flat wires. They have lower torque than motor springs and are regularly applied to make up the stainless steel components of watches.

They are made to provide torsion, which means they can sometimes be used instead of more traditional torsion springs because they can rotate in circular movements. So, rather than being twisted and exerting a force (or torque) in the opposite direction, the force of a clock spring involves the axis of an object – resulting in it being pushed onto another object by the outer edge of the spring.

Motor springs, unlike clock springs, are able to store high levels of energy, allowing them to work with high degrees of stress in applications such as windshield wipers and car engines.

We understand that different springs are needed for specific applications, and so, no matter what type of spring you require, we can create a bespoke solution that works for you.

As motor spring manufacturers, we have a wealth of experience designing and producing motor springs and can supply both standard and bespoke springs as needed.

We pride ourselves on meeting the most challenging demands. So if you require more information about our motor springs or any of our other products, please get in touch and we can discuss your upcoming project.