The drive toward increased sustainability in manufacturing has never been higher as more companies within the industry join this commitment to creating an ecologically improved and profitable industry.

This shift to a more eco-friendly approach may seem like something that has only just begun, but it has been an evolving part of the manufacturing industry in Ireland for years, with many steps being taken toward this goal.

Sustainability Goals in Manufacturing

There have been substantial announcements recently to make manufacturing far more eco-friendly. Phrases such as NetZero 2050 and the green industrial revolution are becoming commonplace as these environmentally friendly initiatives affect more of the industry.

As spring suppliers, we took a great interest in the COP26 event, which was a significant moment for sustainability in manufacturing. The COP26 event was a global United Nations summit addressing climate change and how countries plan to combat it.

COP26 was held in November 2021 in the UK after a significant delay from the previous year due to the pandemic. This is the 26th event for the Conference of the Parties (or COP), which consists of all the United Nations countries that signed the UNFCC in 1994 (the United Nations Framework Convention on Climate change). The importance of COP is the opportunities it provides for a more effective, unified approach to combating climate change across the world and at every level of the industry. For example, at COP26, the UK launched an energy transition council. This council unites 20 governments and over 15 international institutions to support transitions and technical assistance to clean power.

How does COP26 affect the manufacturing sector? First, it has increased the already present demand for companies to embrace sustainability through decarbonisation. The new carbon NetZero targets set during the COP26 focus more on the electricity and gas parts of manufacturing’s high energy usage. This will affect manufacturing significantly within the UK as half its energy is imported.

Positive Growth

One successful way of supporting these green movements is the manufacturing industries’ attempts to create a circular economy. This is the concept of creating products more sustainably with lean manufacturing. By manufacturing from recycled materials, companies save significant energy losses compared to making every product from new, raw resources.

As all manufacturers work toward these positive goals, the real question becomes, how can it be achieved whilst still being competitive within the market? Every business needs to adapt to thrive, and discovering new ways of remaining compliant and competitive is no different. Technology seems to be the key to balancing both of these.

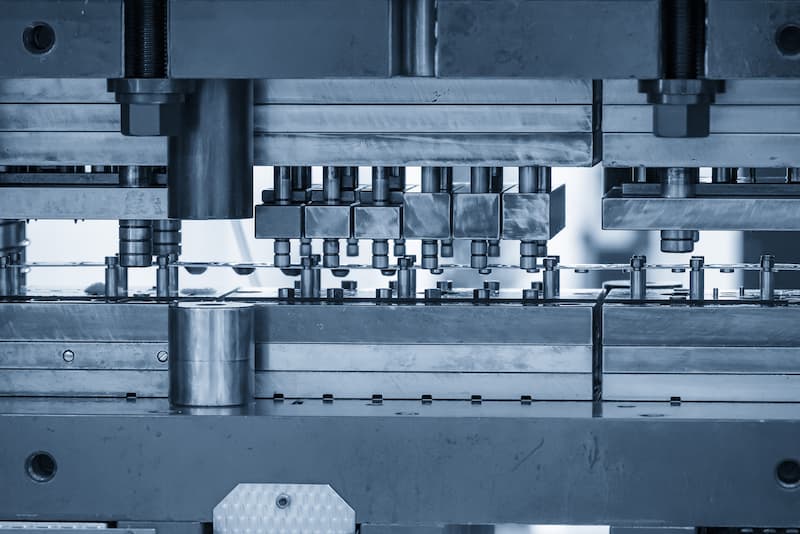

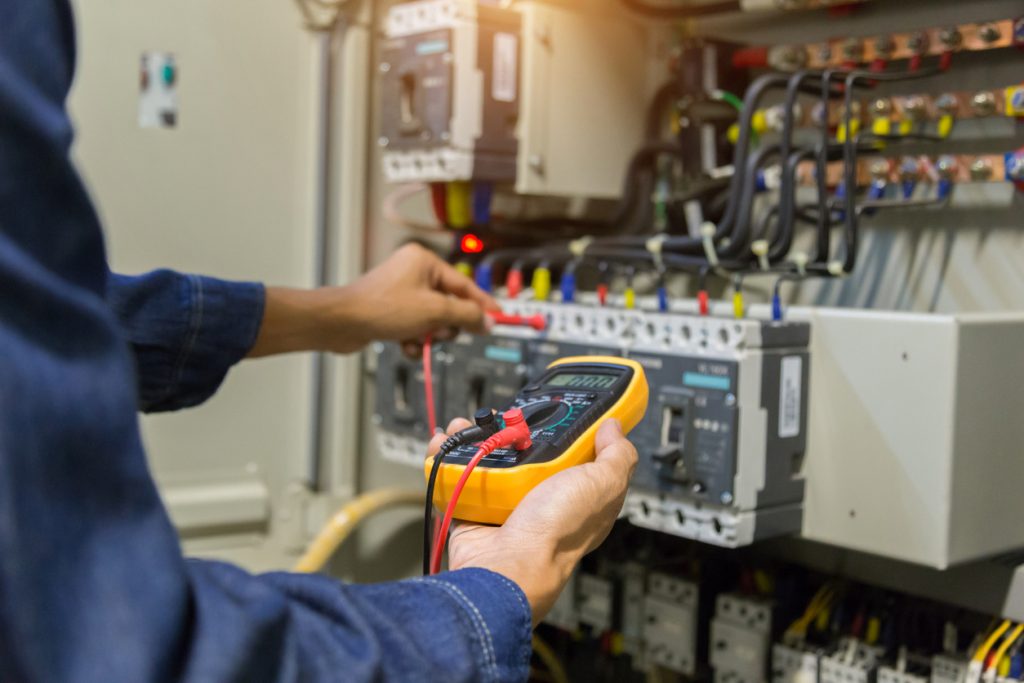

Technology has helped improve manufacturing in many different ways; whether it’s the development of CNC machines or assistive software, it is vital for the future of manufacturing, more so now than ever before.

Technology and manufacturing have developed a close partnership in many ways. These digital solutions have helped support the already successful lean manufacturing processes, improving their waste reduction and efficiency. Beyond the methods themselves, these technological improvements have given the industry increased visibility of its broader operations and workflows, thereby helping identify the wasteful areas and reduce emissions.

Building Profitable Relationships

As experienced gas spring manufacturers, we know that manufacturing has gained significantly from its relationship with technology. So there are potentially infinite benefits ahead through continuing this partnership, including supporting sustainability. But it’s essential that when choosing your partner, you make sure they have similar environmental goals. Exploring the environmental attitudes of your potential partners helps build a sustainable, greener workflow from start to finish.

Since COP26, technology providers have recognised the need for urgency to support sustainability within manufacturing.

When there is a unity of manufacturers, technology providers and customers that all share a vision of increased sustainability, the benefits to the environment are remarkable.

What Does the Future Hold?

Sustainability isn’t simply a single problem that can be finished. Combating climate change will require a persistent shift in operational processes and attitudes to maintain a meaningful impact. This will lead to commitments to lean manufacturing and embrace the waste hierarchy and many other ideas that support manufacturing whilst having a minimal environmental impact.

While the world’s governments are putting measures to increase sustainability, the industry must realise that it doesn’t need to wait for permission to improve its ecological status. The relationships developed between manufacturing and technology have proven to be an immensely effective tool for improvement. By exploring new opportunities, this partnership will achieve staggering results for both sides.

Professional Bespoke Springs, Wireforms and Pressings

At European Springs Ireland, we believe that transparent, continuous engagement and discussions between our technology partners will be essential for developing these relationships and discovering new innovative ways to improve sustainability and efficiency.

Additionally, our expert team of engineers is committed to maintaining effective communication with our client base. Working together, we have had many years of success with manufacturing clock springs and many other bespoke spring designs, pressings and wireforms.

You can read more about our manufacturing processes here, and if you have a product that requires high-quality springs or pressings, please don’t hesitate to contact us today, and one of our team will answer any questions.